Overview

- Thermal Cutting/Coping Line

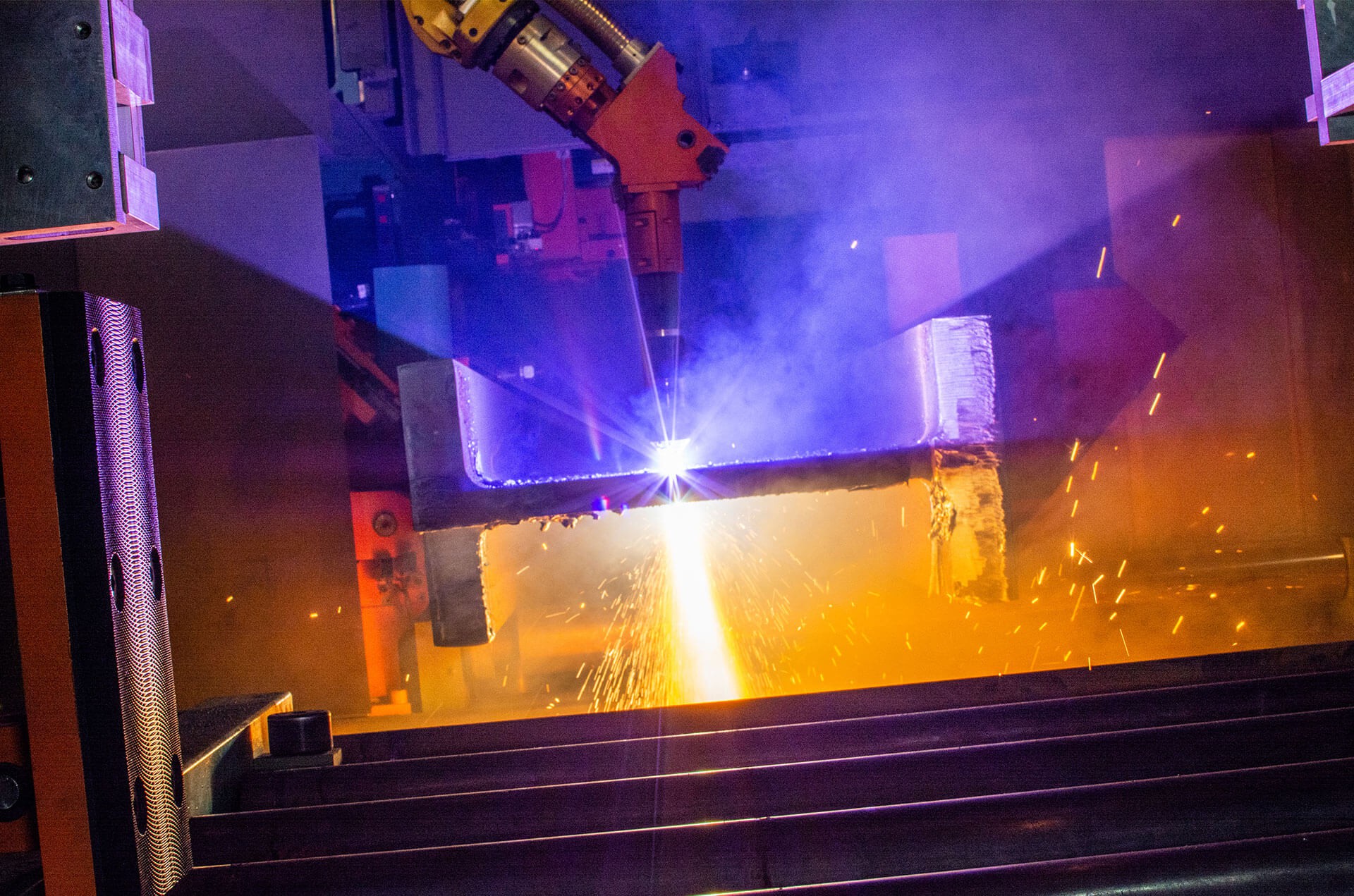

- Fanuc Robot Arm

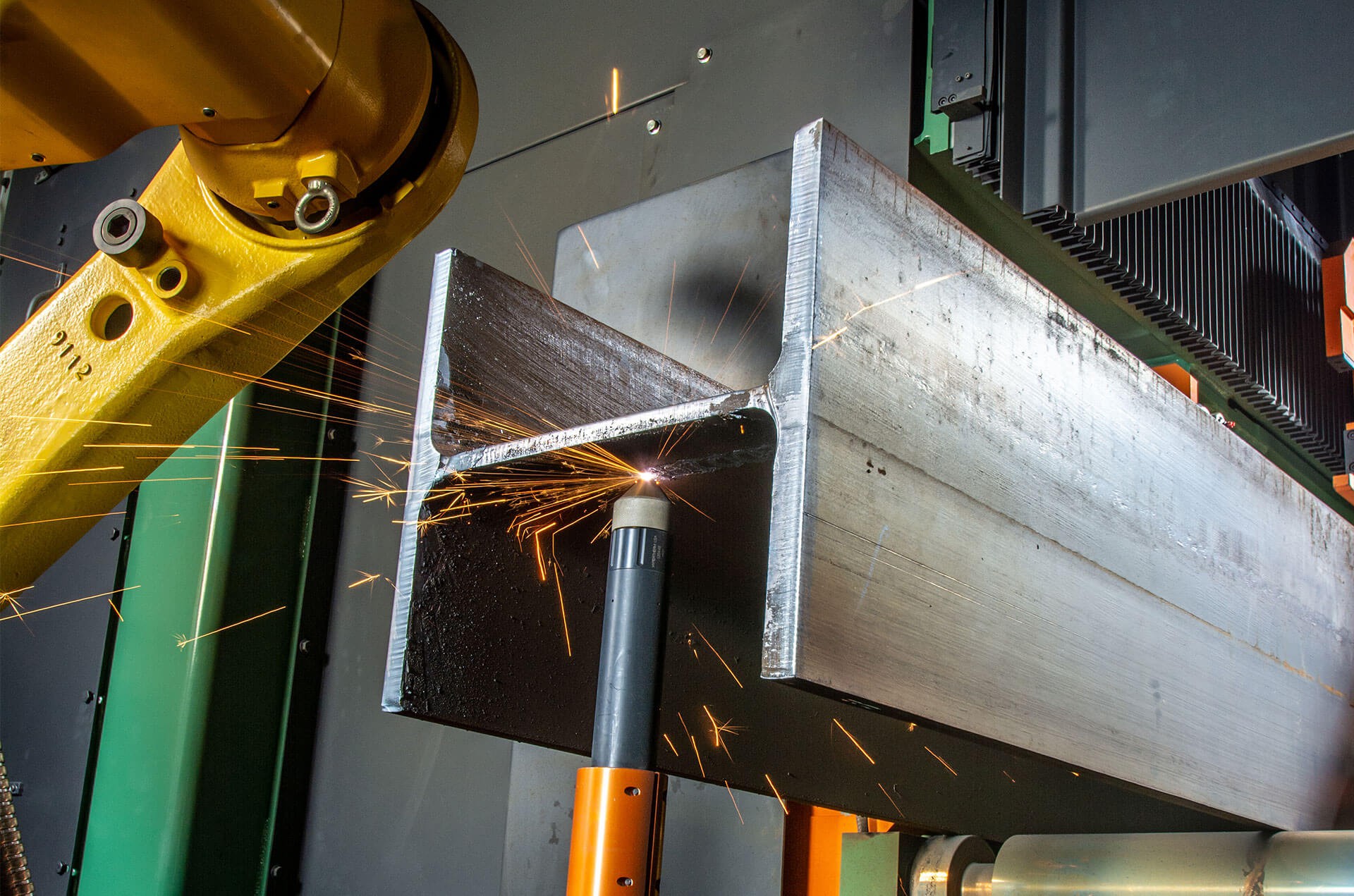

- Robotic Plasma Cutting

- Robotic Oxy-Fuel Cutting

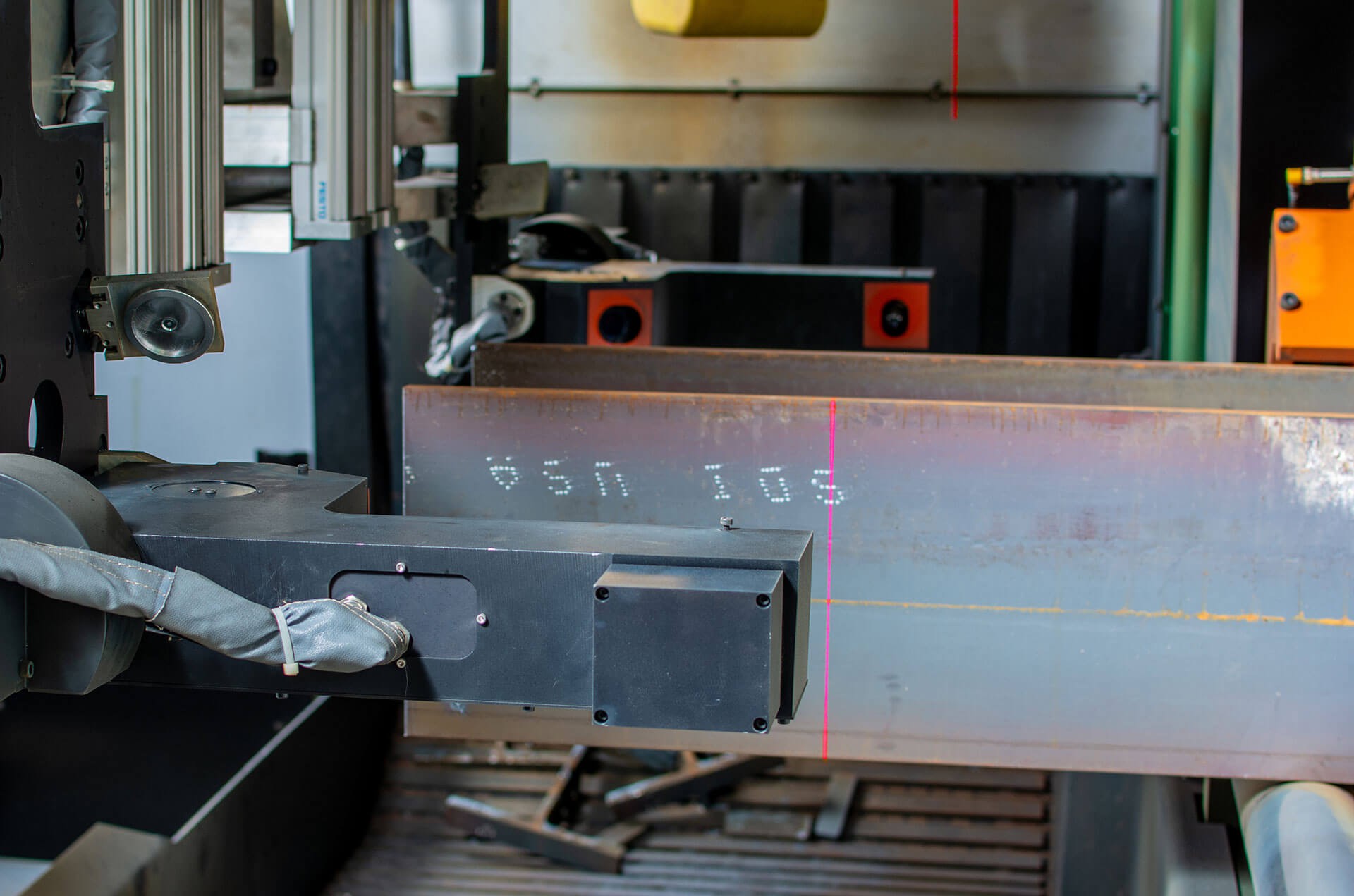

- Hypertherm Plasma ArcWriting

- Automated Tool Changer

- 3D Vision Scanning System

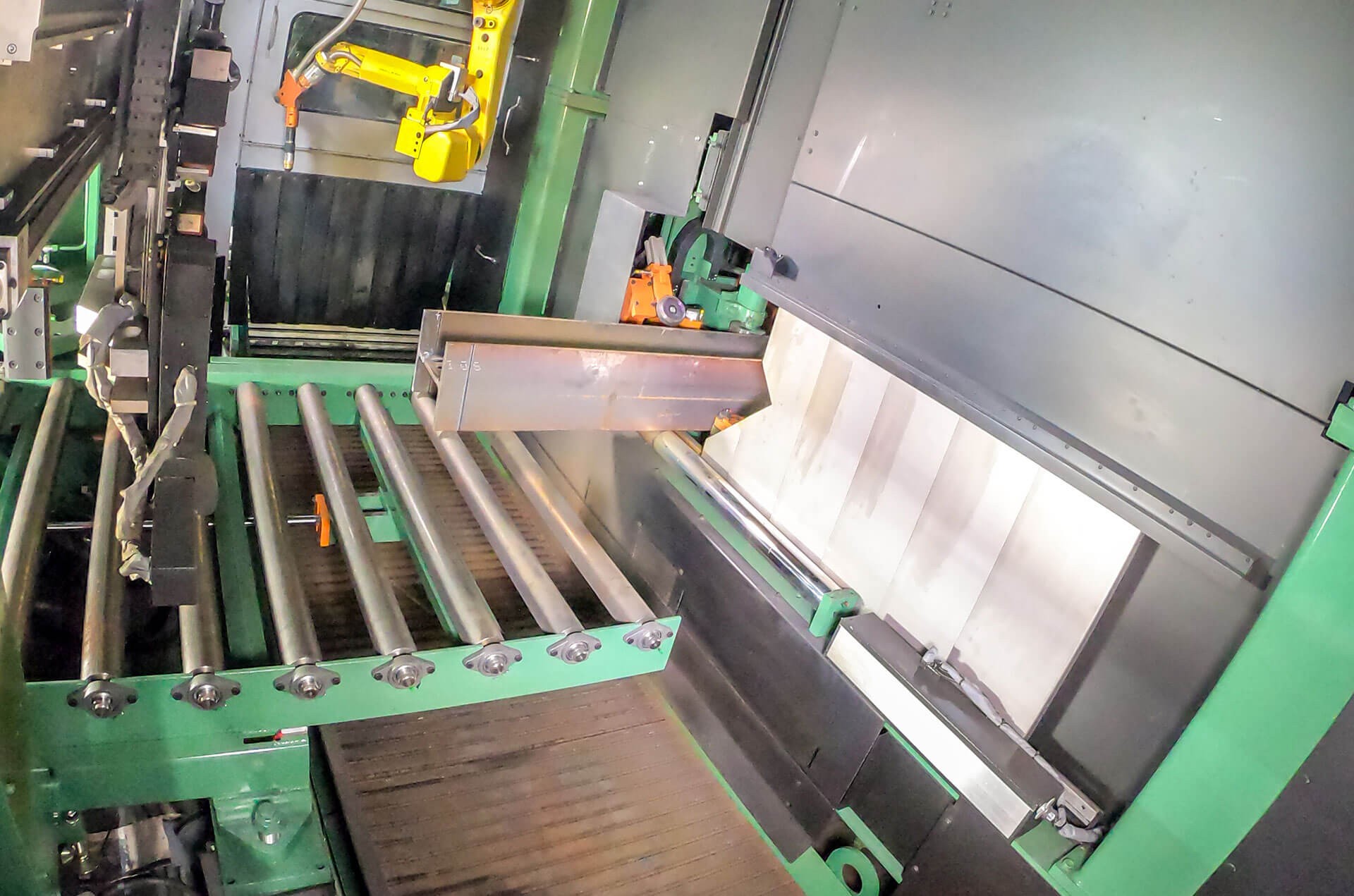

- Telescoping Material Support

- Remnant Removal System

- Scrap Conveyor

- Superior Clamping System

- Robust Machine Housing

- 360º Processing

- Modular Control

- Advanced Software

Plasma Cut

Oxy-Fuel Cut

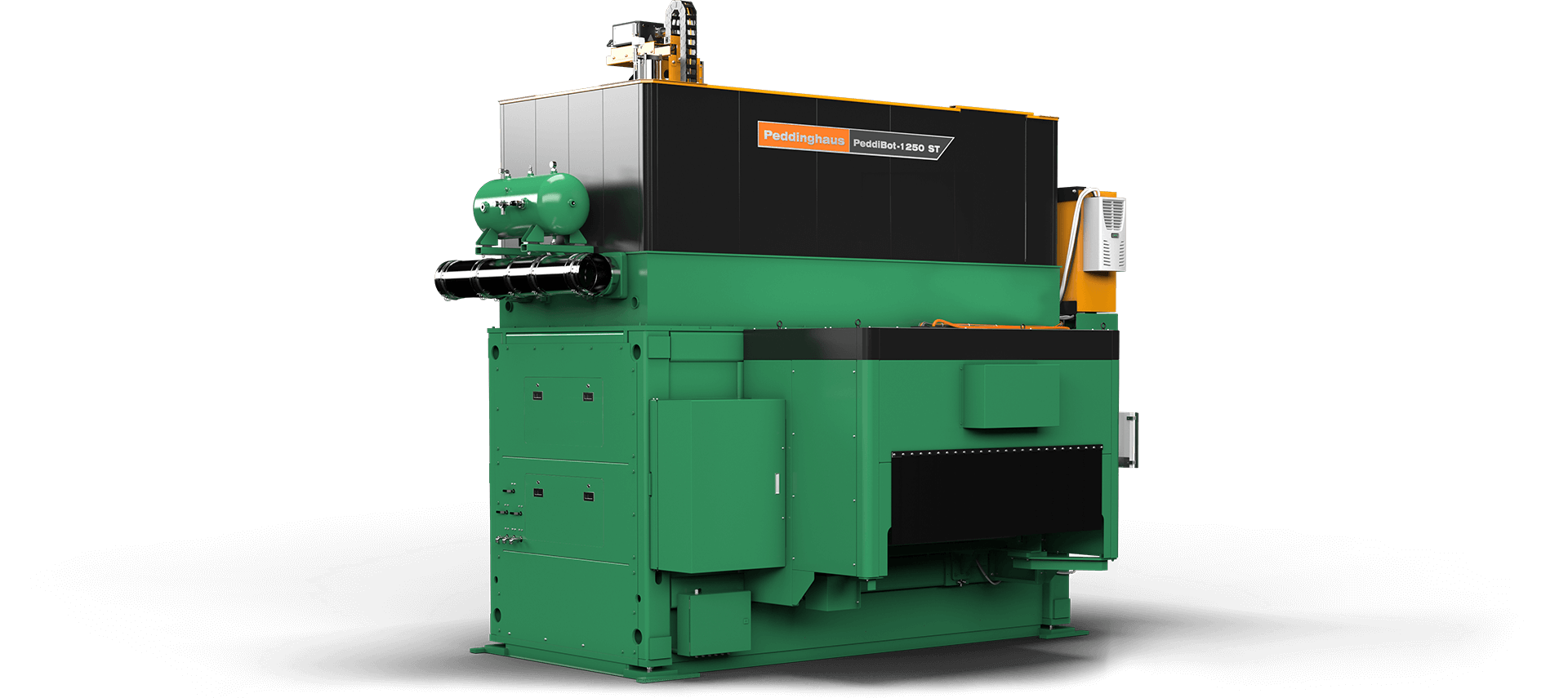

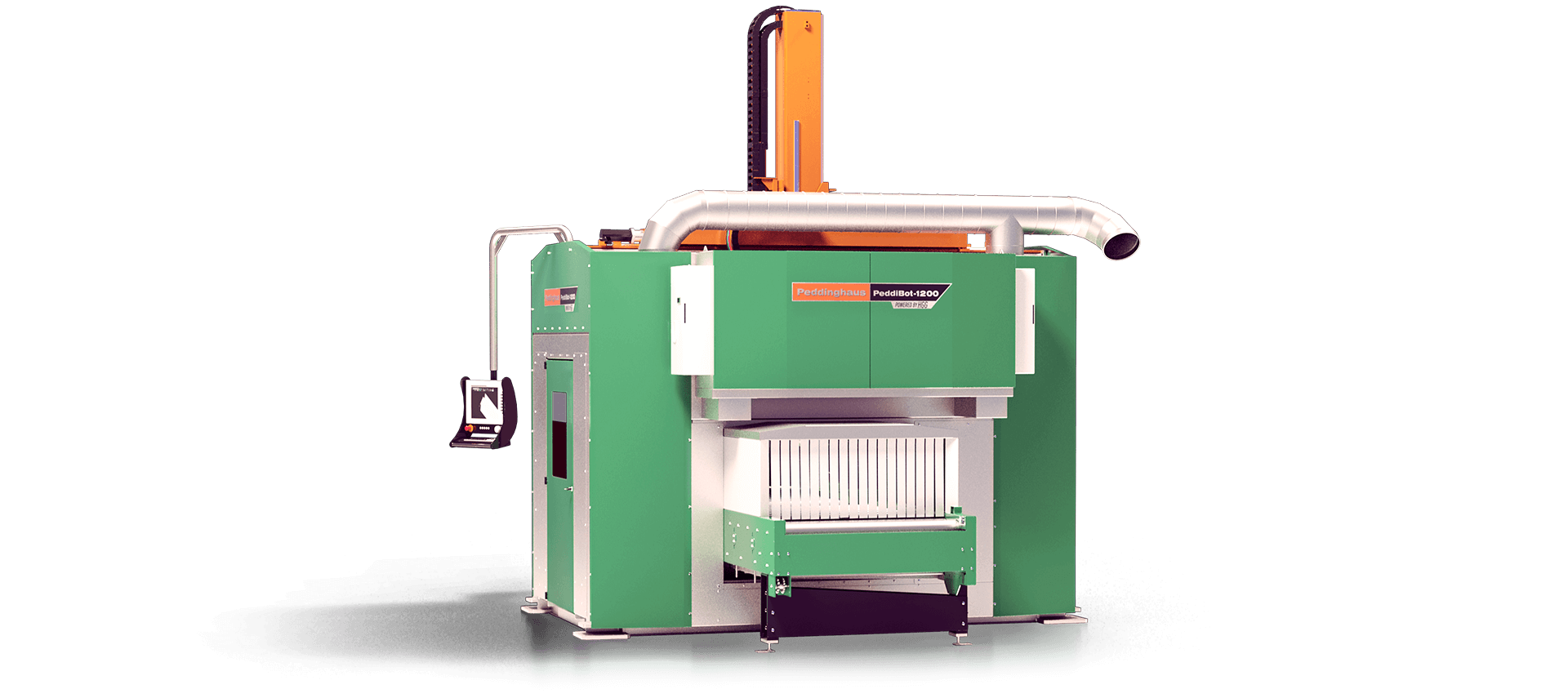

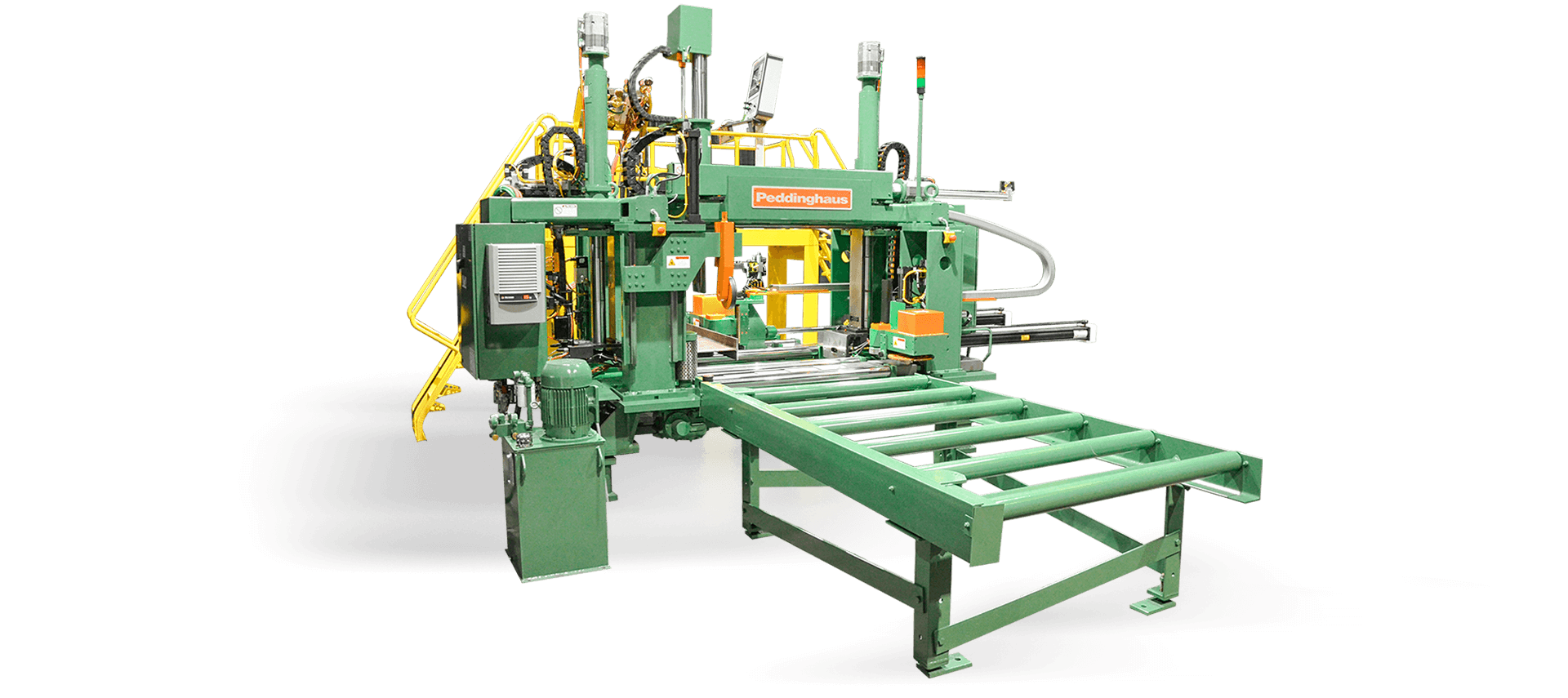

Higher Capacity Processing for Steel

You asked and we listened! The PeddiBot-1250 robotic structural steel fabrication machine is the first of its kind to feature individual capabilities for plasma cutting, oxy-fuel cutting and layout marking all within one machine.

The PeddiBot Heavy Duty Edition

Designed specifically for the structural steel market, this intelligent machine falls nothing short of robust and can more than endure the tough environments that are most common in the steel industry.

Robotic Plasma Cutting Meets Robotic Oxy-Fuel Cutting

The PeddiBot-1250 comes equipped with a Hypertherm HPR400XD plasma cutting system. Designed to maximize productivity with faster cutting speeds, this system is capable of processing up to 3” (80 mm) thick material. Plasma cutting is supplemented by an oxy-fuel cutting system configured to accommodate material thickness of up to 6” (150 mm)!

Robotic Arm Assembly

Each of the PeddiBot-1250’s torches are controlled by a 6-axis Fanuc robot. Torque detection ensures the work zone is clear from any obstructions prior to processing, while torque feedback is then used to detect and avoid any possible robot collisions with the material. Further eliminating downtime, the PeddiBot-1250 makes quick work of tool changes with three conveniently positioned torches for unobstructed access.

Integrated Hypertherm ArcWriting

Multi-axis plasma layout marking is a long-lasting and economical solution. Faster than carbide scribing and easier to maintain than a laser, the PeddiBot-1250 utilizes modern ArcWriting technology. Completely visible through rust and scale, ArcWriting technology reduces error from manual layout and marking of weld data onto a profile.

3D Vision Scanning System

The PeddiBot-1250 comes equipped with a state-of-the-art 3D scanning system. This configuration creates a precise read of the material being processed without the need for continual probing. Peddinghaus’ 3D vision scanning system operates through 4 modern hybrid cameras and 4 lasers that detect each surface of the material, offsetting the robot to match the true material profile.

Telescoping Material Support Conveyor

Material exiting the PeddiBot-1250 is loaded onto an advanced telescoping material support conveyor. This enhanced conveyor system is designed to bridge the space between support rollers when processing small or thin material. The conveyor is retracted once the robot is in operation.

Remnant Removal System

For short parts and remnant pieces, the remnant removal system grabs material from the machine and accurately positions parts into the work zone to complete processing of the piece. A scrap conveyor located underneath the work zone catches any falling debris and transfers scrap and small parts to the side of the machine.

Plate Processing Capabilities

The PeddiBot-1250 sets a new standard by offering an entire fabrication center in a single machine. For fabricators looking to increase plate processing capacity without losing shop space, the added ability to run plate through the PeddiBot-1250 allows for continuous processing without the footprint of another machine.

PeddiBot-1250 Advanced Software

Developed by Peddinghaus, this platform executes features for robotic tool path creation in multiple project environments. The advanced software accepts industry-standard DSTV files and is compatible with Raptor 3D CAD/CAM Software by Peddinghaus. Once material has been scanned, a real-time 3D point cloud is displayed for easy monitoring of each piece being processed.

Higher Capacity Processing for Steel

You asked and we listened! The PeddiBot-1250 robotic structural steel fabrication machine is the first of its kind to feature individual capabilities for plasma cutting, oxy-fuel cutting and layout marking all within one machine.

The PeddiBot Heavy Duty Edition

Designed specifically for the structural steel market, this intelligent machine falls nothing short of robust and can more than endure the tough environments that are most common in the steel industry.

Robotic Plasma Cutting Meets Robotic Oxy-Fuel Cutting

The PeddiBot-1250 comes equipped with a Hypertherm HPR400XD plasma cutting system. Designed to maximize productivity with faster cutting speeds, this system is capable of processing up to 3” (80 mm) thick material. Plasma cutting is supplemented by an oxy-fuel cutting system configured to accommodate material thickness of up to 6” (150 mm)!

Robotic Arm Assembly

Each of the PeddiBot-1250’s torches are controlled by a 6-axis Fanuc robot. Torque detection ensures the work zone is clear from any obstructions prior to processing, while torque feedback is then used to detect and avoid any possible robot collisions with the material. Further eliminating downtime, the PeddiBot-1250 makes quick work of tool changes with three conveniently positioned torches for unobstructed access.

Integrated Hypertherm ArcWriting

Multi-axis plasma layout marking is a long-lasting and economical solution. Faster than carbide scribing and easier to maintain than a laser, the PeddiBot-1250 utilizes modern ArcWriting technology. Completely visible through rust and scale, ArcWriting technology reduces error from manual layout and marking of weld data onto a profile.

3D Vision Scanning System

The PeddiBot-1250 comes equipped with a state-of-the-art 3D scanning system. This configuration creates a precise read of the material being processed without the need for continual probing. Peddinghaus’ 3D vision scanning system operates through 4 modern hybrid cameras and 4 lasers that detect each surface of the material, offsetting the robot to match the true material profile.

Telescoping Material Support Conveyor

Material exiting the PeddiBot-1250 is loaded onto an advanced telescoping material support conveyor. This enhanced conveyor system is designed to bridge the space between support rollers when processing small or thin material. The conveyor is retracted once the robot is in operation.

Remnant Removal System

For short parts and remnant pieces, the remnant removal system grabs material from the machine and accurately positions parts into the work zone to complete processing of the piece. A scrap conveyor located underneath the work zone catches any falling debris and transfers scrap and small parts to the side of the machine.

Plate Processing Capabilities

The PeddiBot-1250 sets a new standard by offering an entire fabrication center in a single machine. For fabricators looking to increase plate processing capacity without losing shop space, the added ability to run plate through the PeddiBot-1250 allows for continuous processing without the footprint of another machine.