Overview

- Automatic Layout Marking

- Hypertherm Plasma ArcWriting

- Independent Torches

- Roller Feed Measurement

- Surface Detection System

- Siemens Electronics

- Peddinghaus Control

- Raptor Software

Speed

Hypertherm

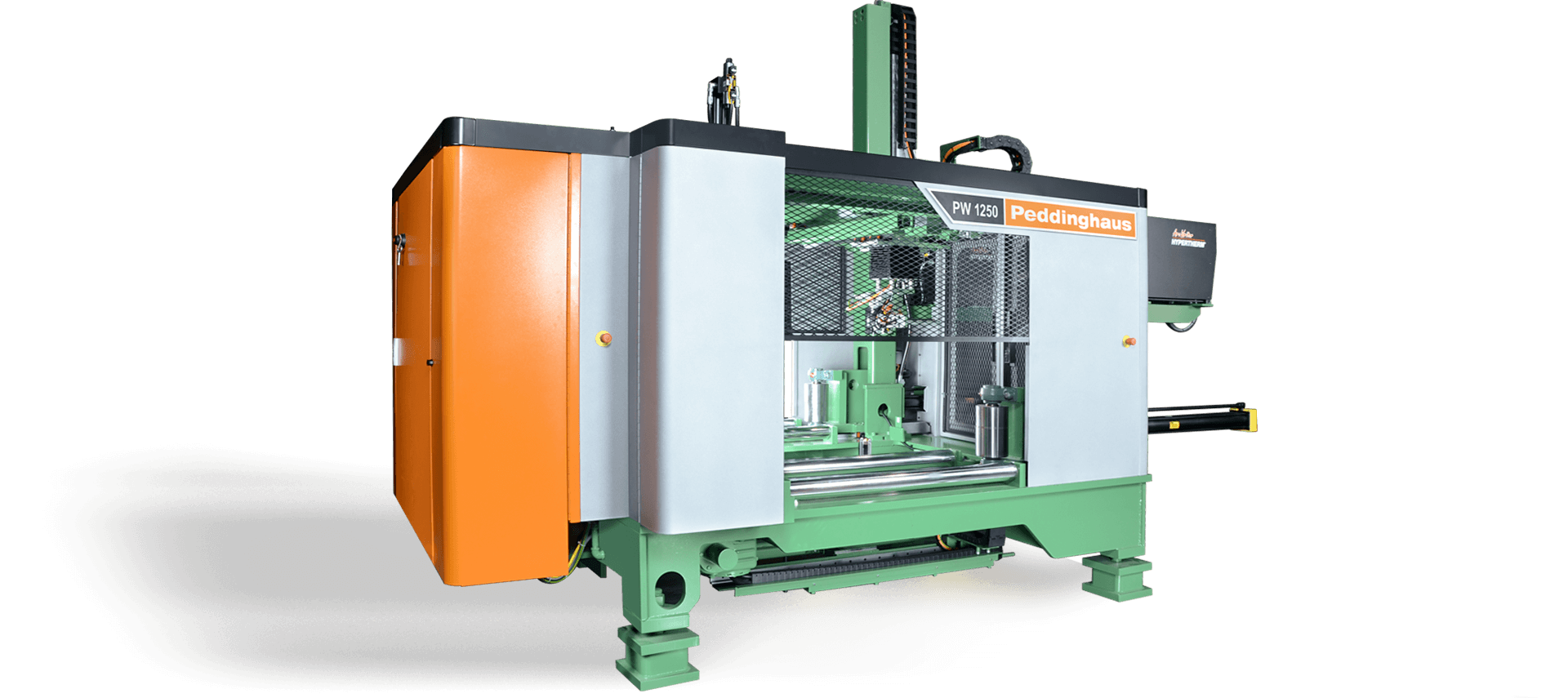

Welcome to CNC Layout Marking

The PeddiWriter automatic layout marking machine is the first of its kind, and has already achieved unprecedented success in the steel industry. With annual labor savings up to $300,000, the PeddiWriter marks as many as 150 profiles in a single shift and equals the work to that of 6 layout technicians.

Layout Your Shop's Future

Designed with the rugged environment of typical fab shops in mind, the PeddiWriter relies on proven Hypertherm plasma technology to automate the processes of layout and fit up. The PeddiWriter makes non-intrusive layout marks that clearly designate cutting and welding operations.

Hypertherm Plasma ArcWriting

Hypertherm ArcWriting on the PeddiWriter allows for superior marking times, and maximum return on investment. Plasma marking maintains its visibility on all finished surfaces whether they are shot blasted or contain amounts of rust or scale.

Two Independent Torch Assemblies

Two completely independent torch assemblies allow the PeddiWriter to operate at rapid speeds, far surpassing carbide scribing. Each torch operates on a completely independent axis. This allows the machine to mark totally unique characters, on two separate surfaces simultaneously.

Continuous Surface Detection

Unlike traditional processing systems that rely on the need to constantly probe material, the PeddiWriter utilizes a mechanical roller probe system. This allows the machine to maintain distance while marking during a program, eliminating timely probing sequences.

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

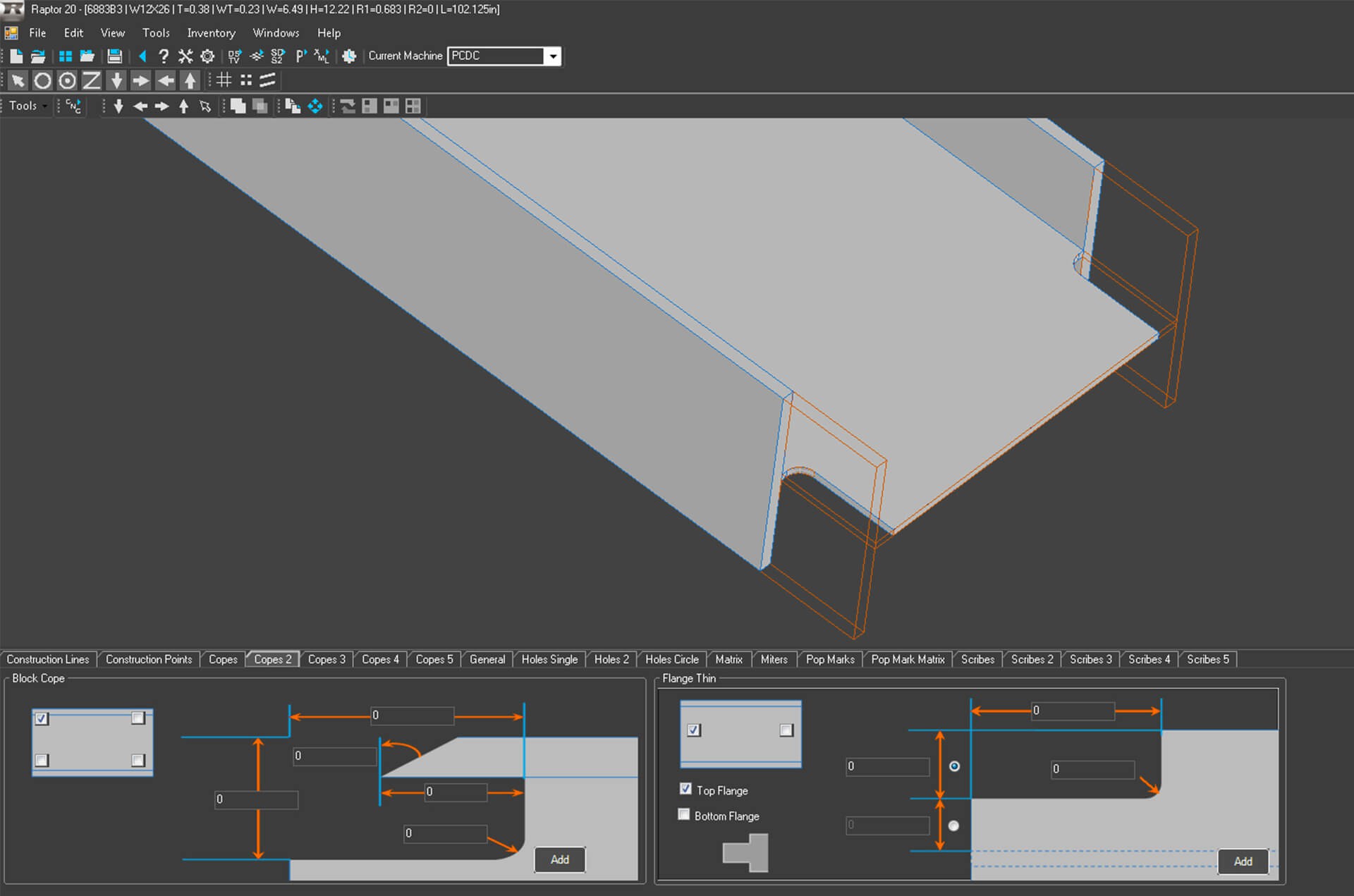

Raptor 3D CAD/CAM Software

Developed by Peddinghaus, Raptor 3D CAD/CAM Software takes CNC innovation further by enabling users to program faster and more accurately. Inspect, modify and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

Welcome to CNC Layout Marking

The PeddiWriter automatic layout marking machine is the first of its kind, and has already achieved unprecedented success in the steel industry. With annual labor savings up to $300,000, the PeddiWriter marks as many as 150 profiles in a single shift and equals the work to that of 6 layout technicians.

Layout Your Shop's Future

Designed with the rugged environment of typical fab shops in mind, the PeddiWriter relies on proven Hypertherm plasma technology to automate the processes of layout and fit up. The PeddiWriter makes non-intrusive layout marks that clearly designate cutting and welding operations.

Hypertherm Plasma ArcWriting

Hypertherm ArcWriting on the PeddiWriter allows for superior marking times, and maximum return on investment. Plasma marking maintains its visibility on all finished surfaces whether they are shot blasted or contain amounts of rust or scale.

Two Independent Torch Assemblies

Two completely independent torch assemblies allow the PeddiWriter to operate at rapid speeds, far surpassing carbide scribing. Each torch operates on a completely independent axis. This allows the machine to mark totally unique characters, on two separate surfaces simultaneously.

Continuous Surface Detection

Unlike traditional processing systems that rely on the need to constantly probe material, the PeddiWriter utilizes a mechanical roller probe system. This allows the machine to maintain distance while marking during a program, eliminating timely probing sequences.

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.