Overview

- Angle and Flat Line

- SignoScript Carbide Scribing

- SignoMat Part Stamping

- Roller Feed Measurement

- Minimum Quantity Lubrication

- Superior Clamping System

- Siemens Advanced Control

- Raptor Software

- Punching

- Shearing

- Material Handling

Process

Dual Tool

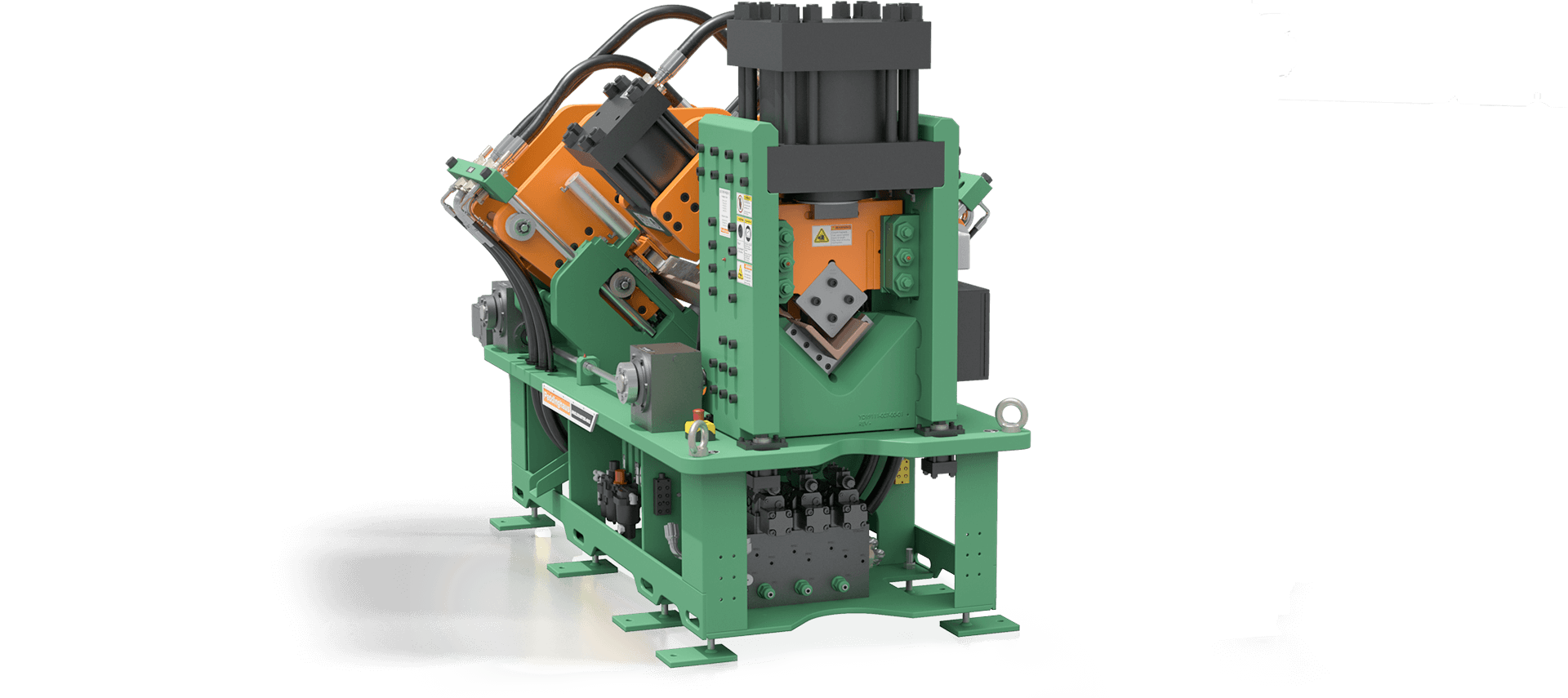

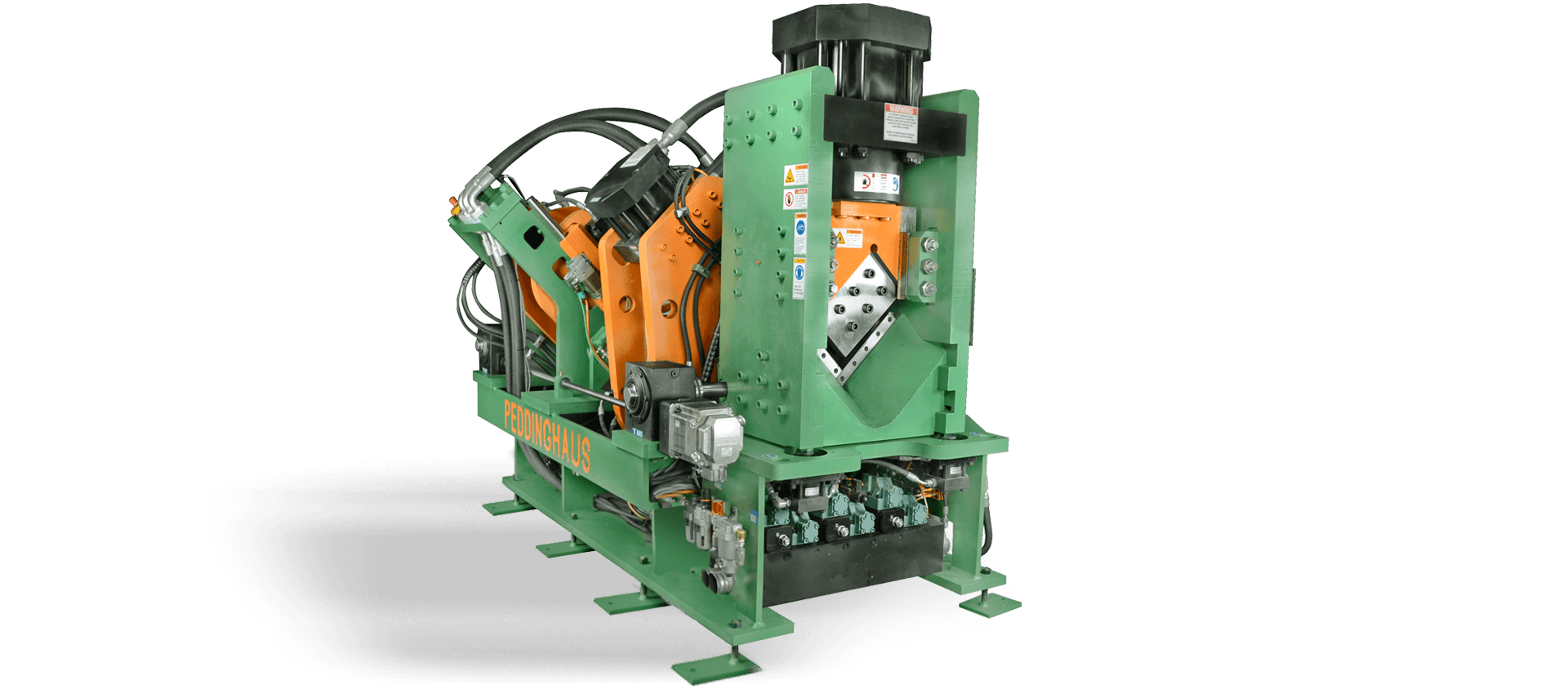

The Standard for Angle and Flat Bar Production

Detail components make up the smallest tonnage of any fabricators' workload, but consistently demand the highest amount of labor. The Anglemaster-643 angle line machine is built to run constant and withstand the test of time in grueling shop environments.

Proven Precision

The preferred choice for fabricators around the world, the Anglemaster-643 allows continuous loading, punching, shearing and unloading for angle and flat stock all in one operation.

Double Tool Punch Press

Two 75 ton punch cylinders each with two punch stations per hydraulic press allow the Anglemaster-643 to apply up to two different hole shapes/sizes per leg. This angle line machine can accommodate shaped holes such as squares, rectangles, obrounds and slots.

Powerful Shearing

The Anglemaster-643 angle line machine uses a single cut 230 ton shear press for the cutting to length angle and flat stock. A single cut shear mechanism eliminates the slug created by double cut shear mechanisms.

SignoScript Carbide Scribing

The SignoScript layout marking attachment eliminates human error in manual layout methods. Complete information is maintained throughout blasting, galvanizing and painting processes.

SignoMat Part Stamping

The SignoMat part stamping unit stamps at an unmatched 1 character per second with a depth of 1/32" (.8 mm) and a total height of 1/2" (12 mm). The unit holds up to 36 characters for complete part marking ability.

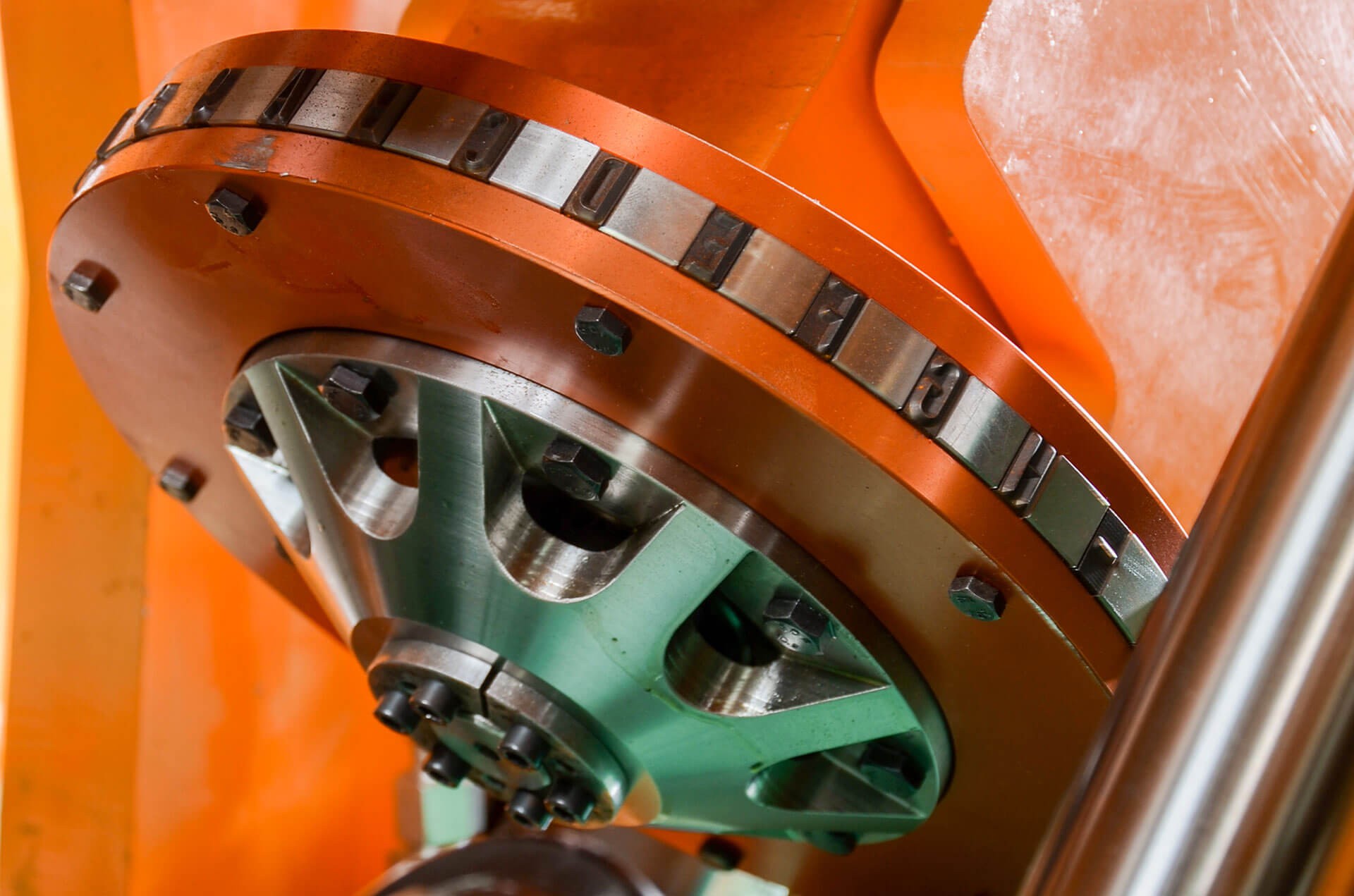

Nonstop Throughput with Roller Feed Technology

Equipped with the Peddinghaus Roller Feed measurement system, the Anglemaster-643 maximizes contact with the material at all times. This Roller Feed technology ensures a constant roll and an accurate measurement given deviations in material.

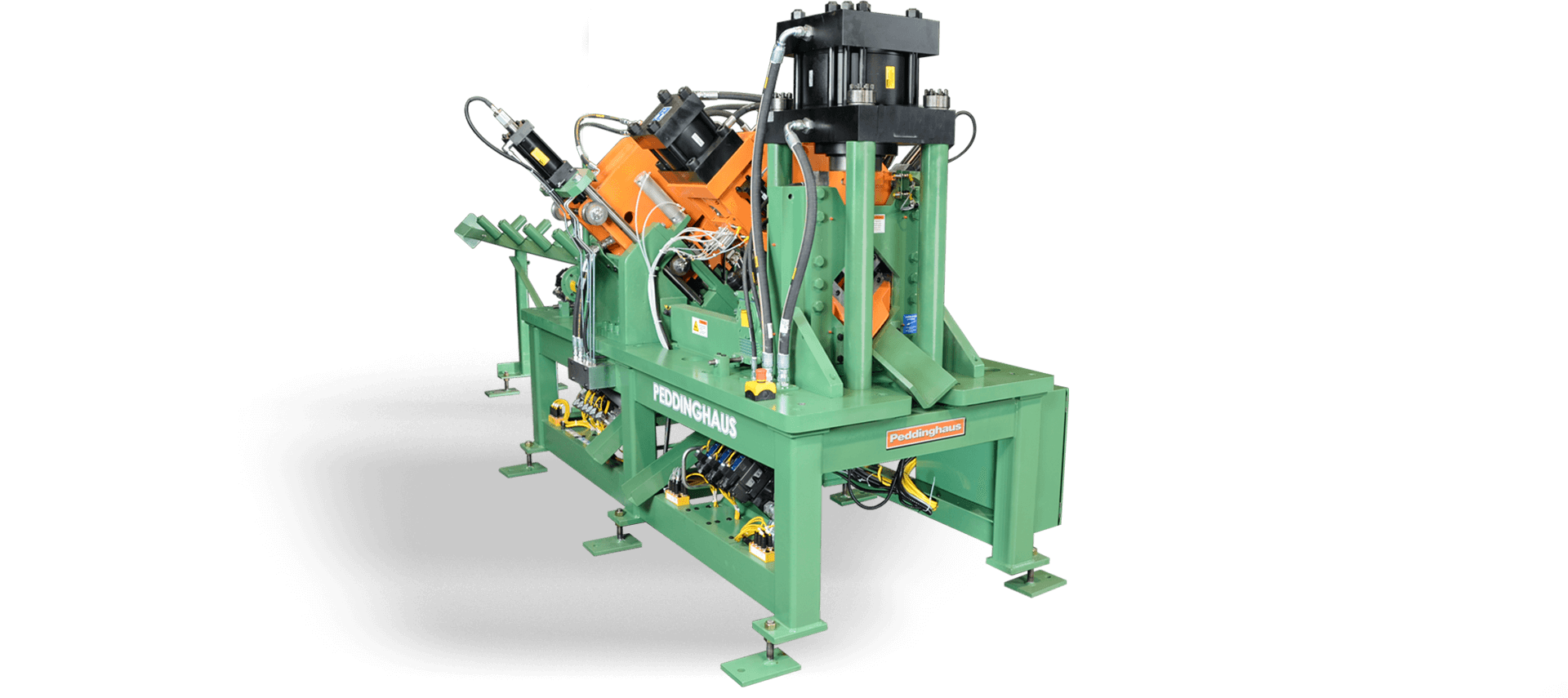

Infeed and Outfeed Material Handling

The infeed and outfeed material handling system, designed for continuous production, keeps the operator safe at all times. As drag chain conveyors move material to the infeed conveyors, power material advance initiates steel into the machine. Once sheared, drive rollers advance the finished parts to the unloading zone.

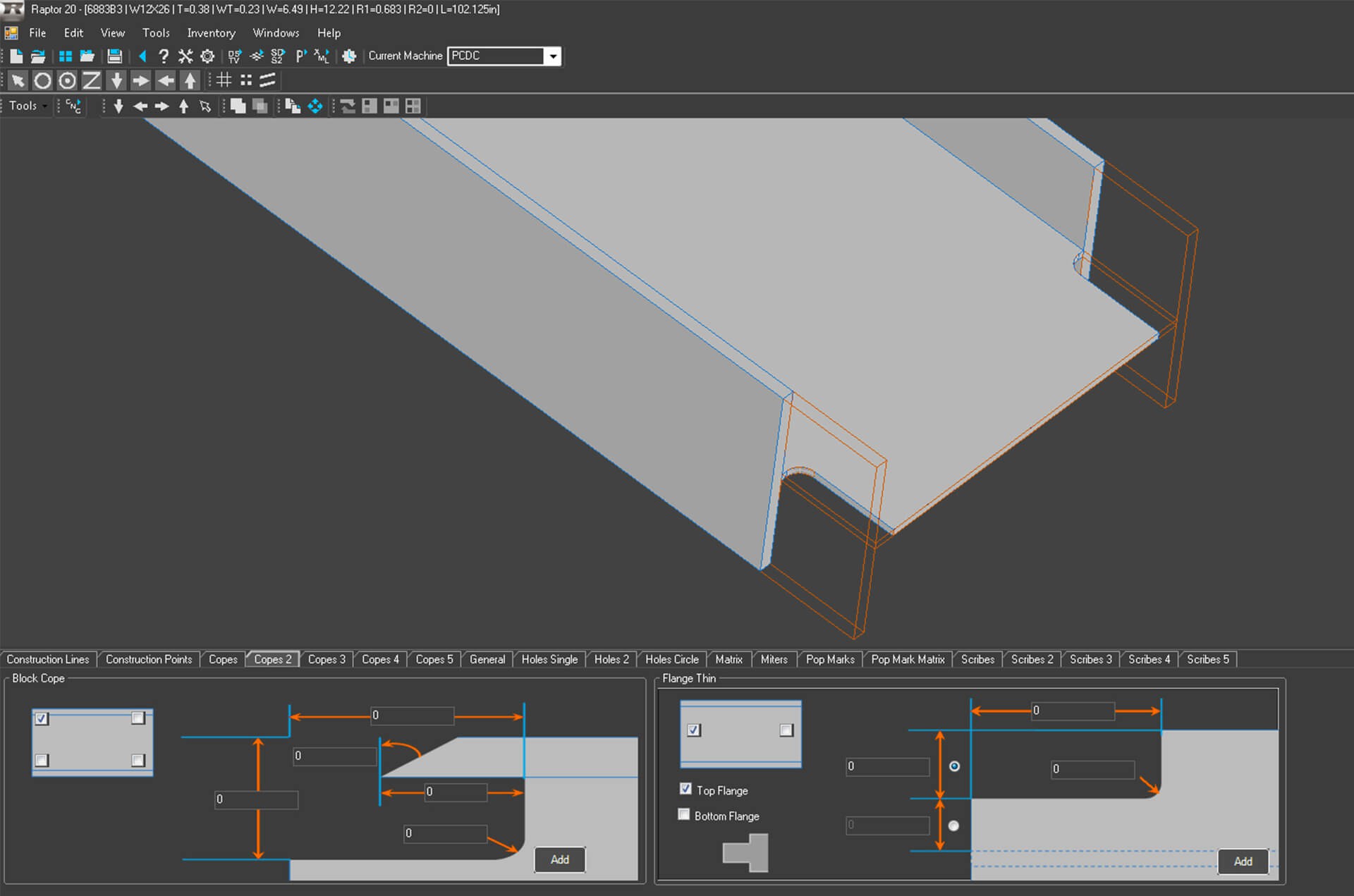

Raptor 3D CAD/CAM Software

Developed by Peddinghaus, Raptor 3D CAD/CAM Software takes CNC innovation further by enabling users to program faster and more accurately. Inspect, modify and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

The Standard for Angle and Flat Bar Production

Detail components make up the smallest tonnage of any fabricators' workload, but consistently demand the highest amount of labor. The Anglemaster-643 angle line machine is built to run constant and withstand the test of time in grueling shop environments.

Proven Precision

The preferred choice for fabricators around the world, the Anglemaster-643 allows continuous loading, punching, shearing and unloading for angle and flat stock all in one operation.

Double Tool Punch Press

Two 75 ton punch cylinders each with two punch stations per hydraulic press allow the Anglemaster-643 to apply up to two different hole shapes/sizes per leg. This angle line machine can accommodate shaped holes such as squares, rectangles, obrounds and slots.

Powerful Shearing

The Anglemaster-643 angle line machine uses a single cut 230 ton shear press for the cutting to length angle and flat stock. A single cut shear mechanism eliminates the slug created by double cut shear mechanisms.

SignoScript Carbide Scribing

The SignoScript layout marking attachment eliminates human error in manual layout methods. Complete information is maintained throughout blasting, galvanizing and painting processes.

SignoMat Part Stamping

The SignoMat part stamping unit stamps at an unmatched 1 character per second with a depth of 1/32" (.8 mm) and a total height of 1/2" (12 mm). The unit holds up to 36 characters for complete part marking ability.

Nonstop Throughput with Roller Feed Technology

Equipped with the Peddinghaus Roller Feed measurement system, the Anglemaster-643 maximizes contact with the material at all times. This Roller Feed technology ensures a constant roll and an accurate measurement given deviations in material.

Infeed and Outfeed Material Handling

The infeed and outfeed material handling system, designed for continuous production, keeps the operator safe at all times. As drag chain conveyors move material to the infeed conveyors, power material advance initiates steel into the machine. Once sheared, drive rollers advance the finished parts to the unloading zone.