Redefining Material Handling Standards

Efficiency in material flow is a critical component of any steel fabricator’s operation. With a unique approach, Kansas City Structural optimized the layout of their machinery to ensure a smooth and rapid movement of material through the main facility, cutting their handling down by over 50%. Wide flange beams are received on the west side of the Peddinghaus system, while tubes, pipes, angle and flat stock are received on the east side. Once a piece of material has been loaded onto the transfer conveyors, it has the freedom to seamlessly transition between different stages of production as needed.

Depending on the project requirements, material is advanced either to the BDL-1250/9D, BDL-1250/9B or PeddiBlast. Owner Tim Olah explains, “Material can flow in either direction, north or south. While some projects require blasting, others may not. In cases where blasting is not needed, material is advanced directly to the drill lines. If blasting is necessary, that process begins as soon as the material hits the conveyor. Blasted material is advanced to the drill lines last.” This flexible arrangement allows Kansas City Structural to accommodate blasting requirements without impeding the speed of other operations.

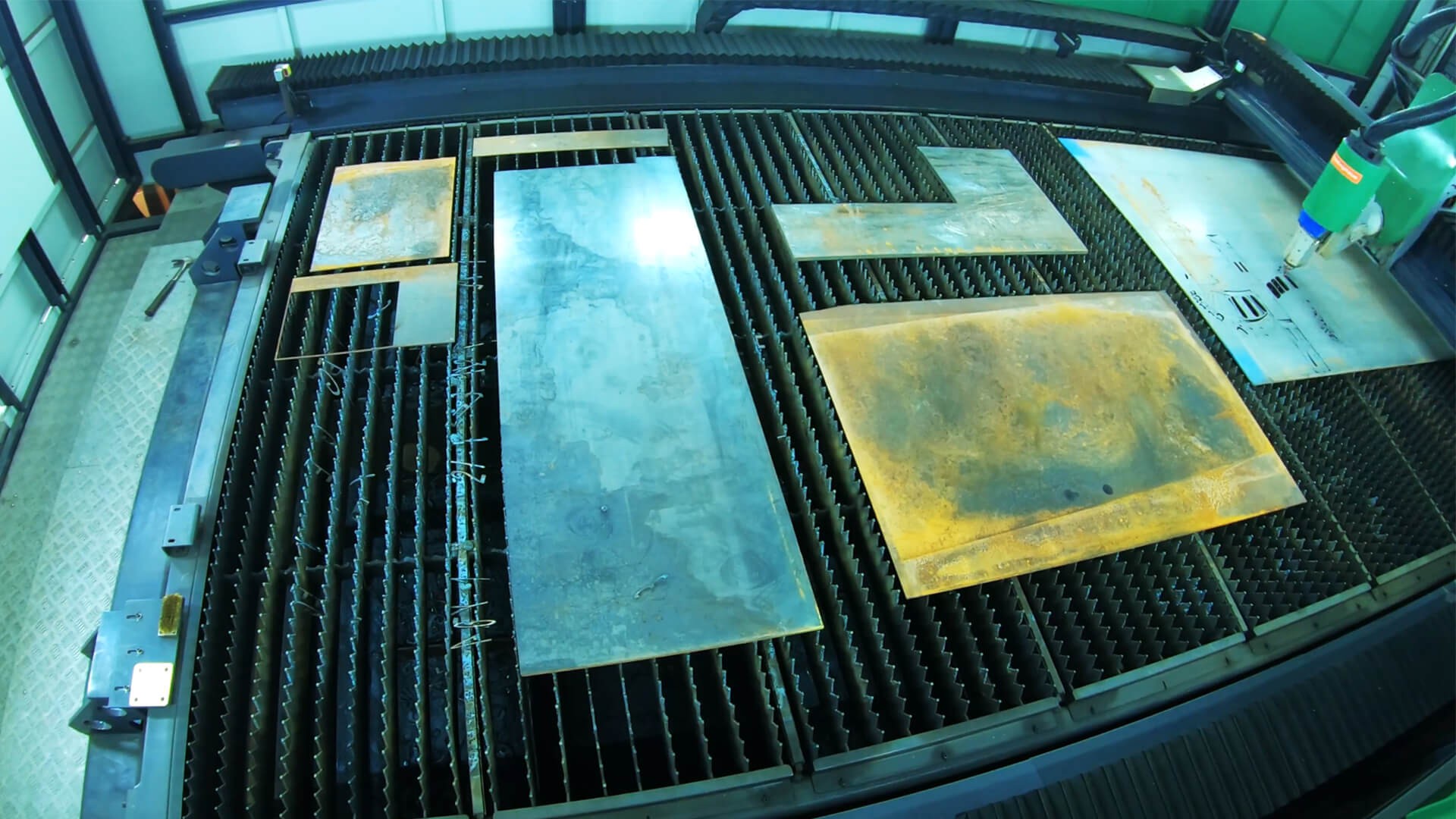

The plate line and the robot were the definitely two biggest leaps we made as far as productivity.

Enter Today for a Chance to Win FREE Machinery

Gift cards and other Peddinghaus merchandise included

46331 mobile

TO

46331

WINNER

Normal text message rates apply. Text “STOP” to opt out. Text “HELP” for help. Up to 3 msgs / month. Terms https://www.peddinghaus.com/terms/1