Overview

- Structural Band Saw

- Miter Cutting

- 7.5 HP Blade Drive Motor

Blade

Cut

Miter Cut Band Saw

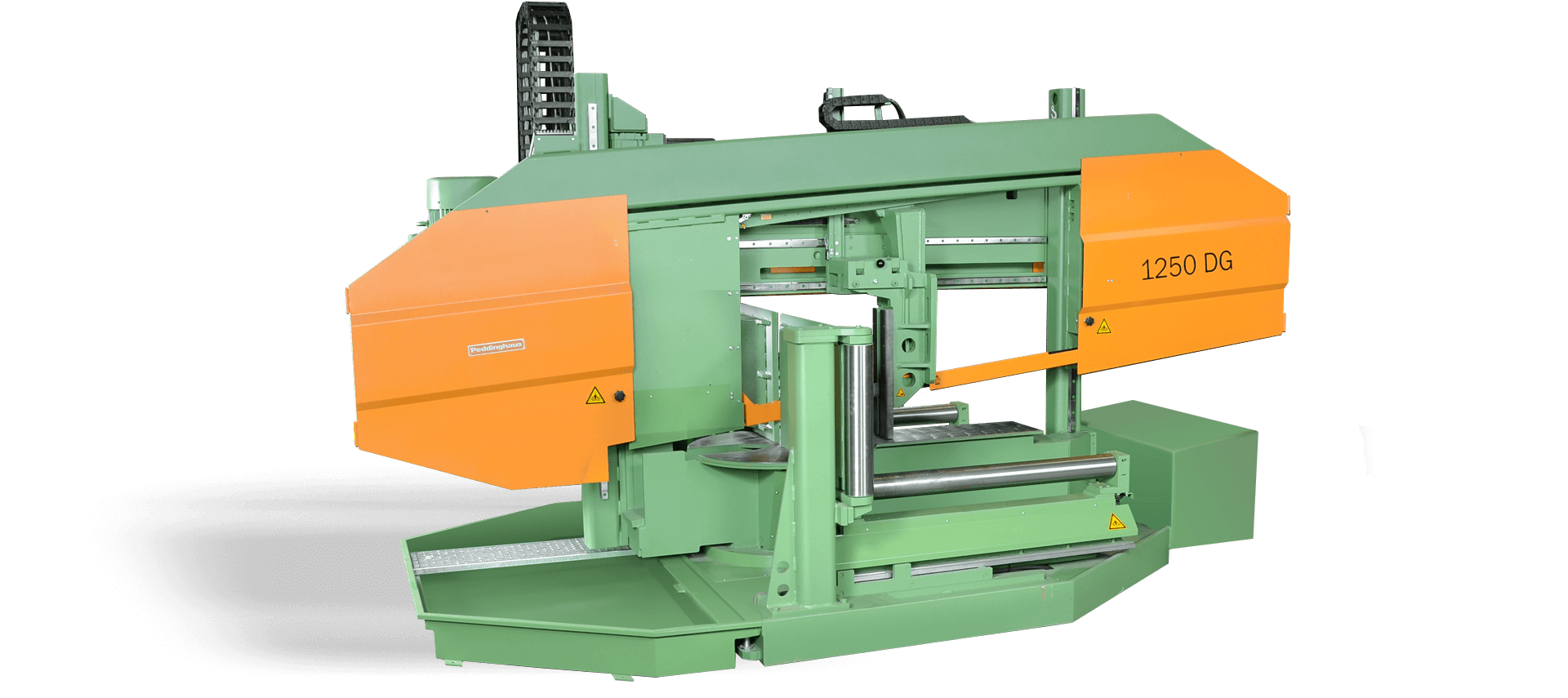

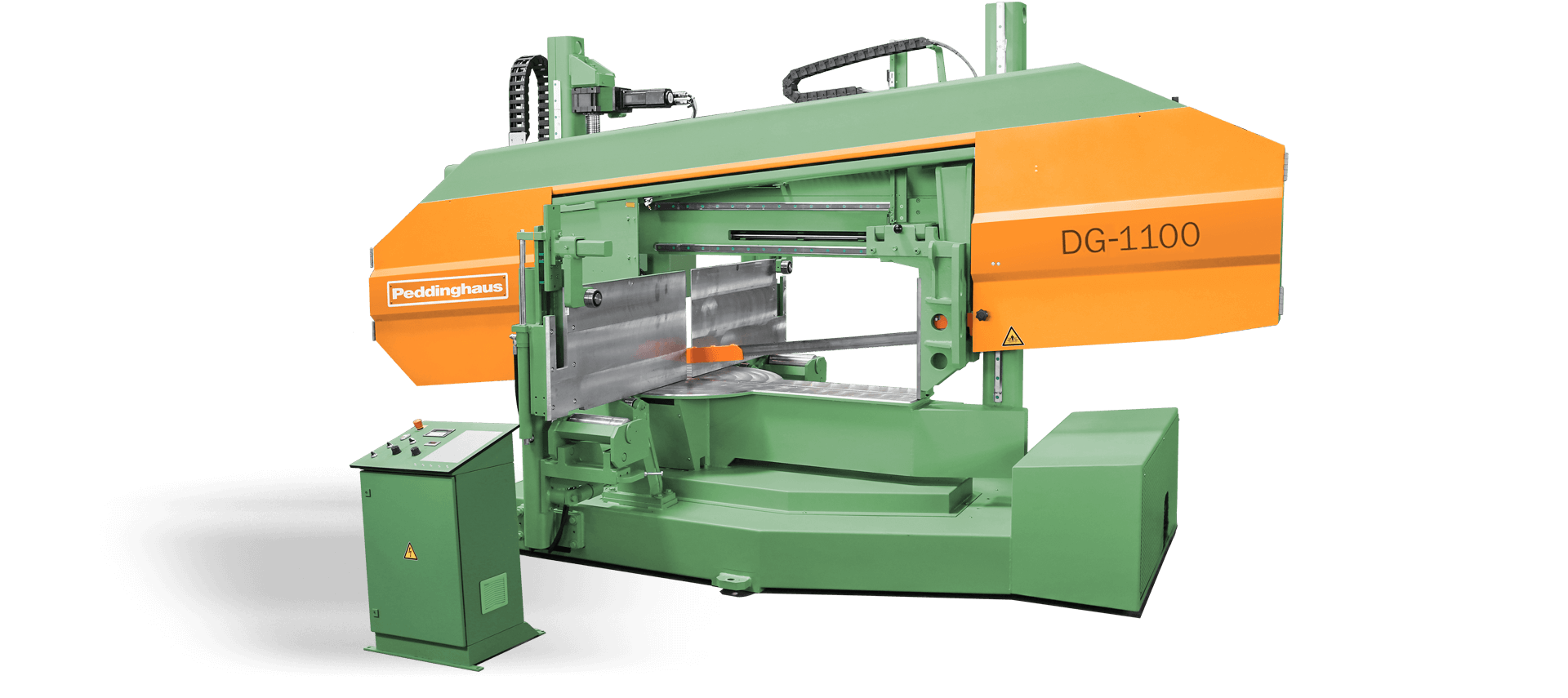

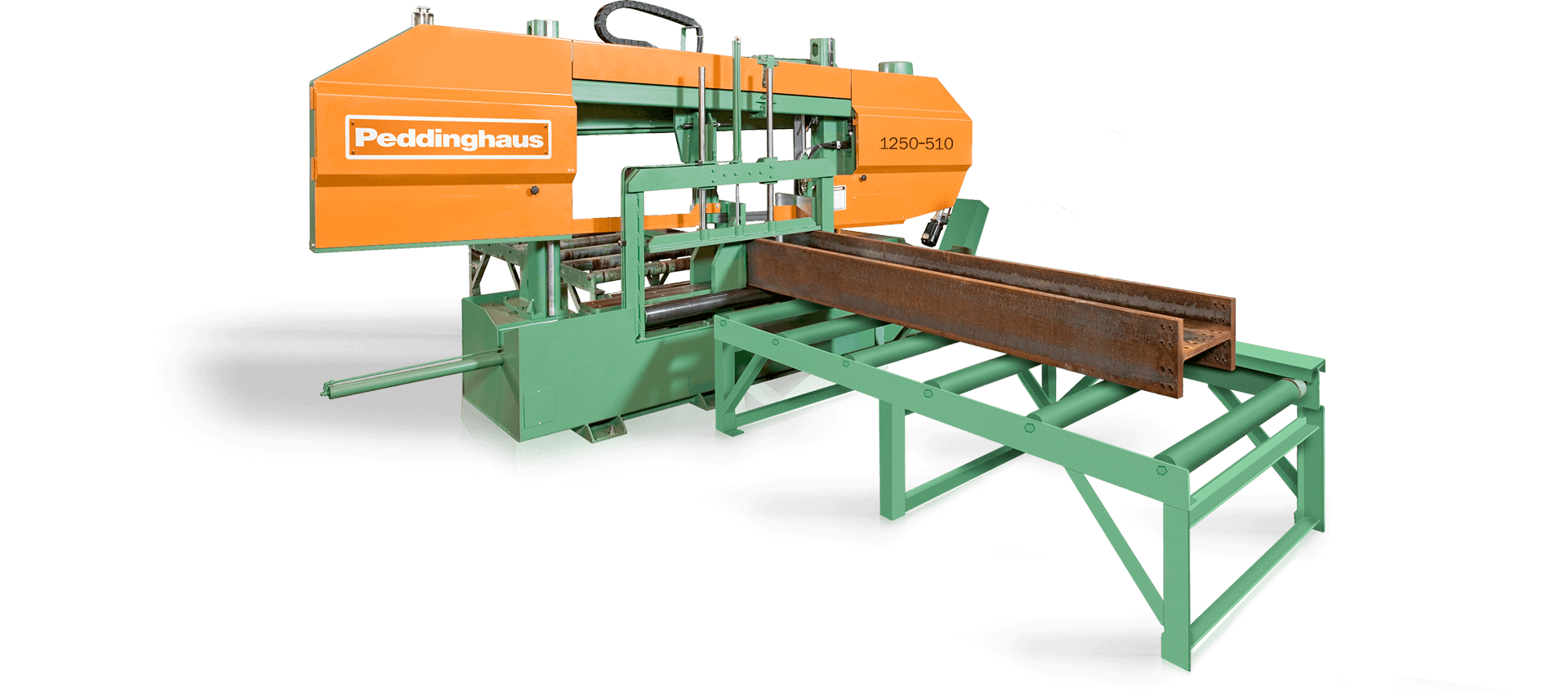

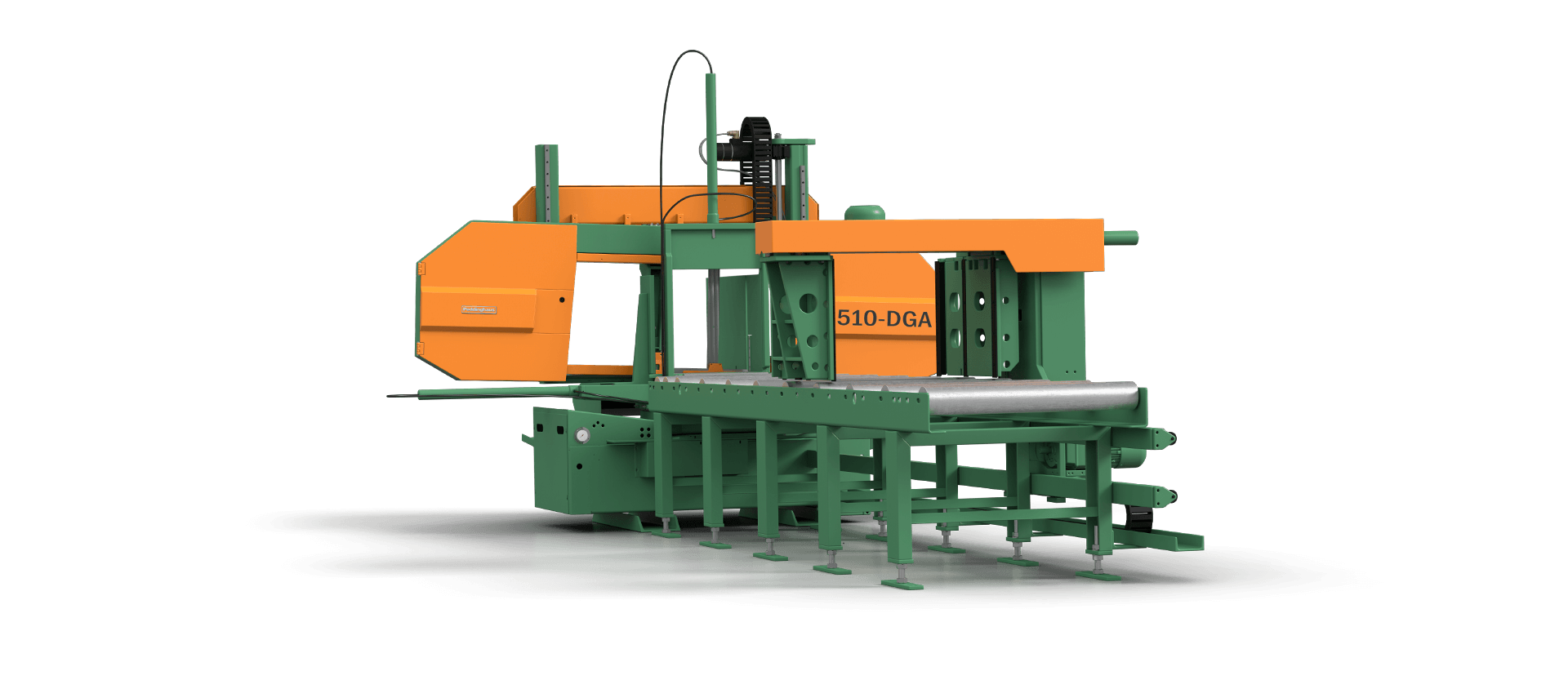

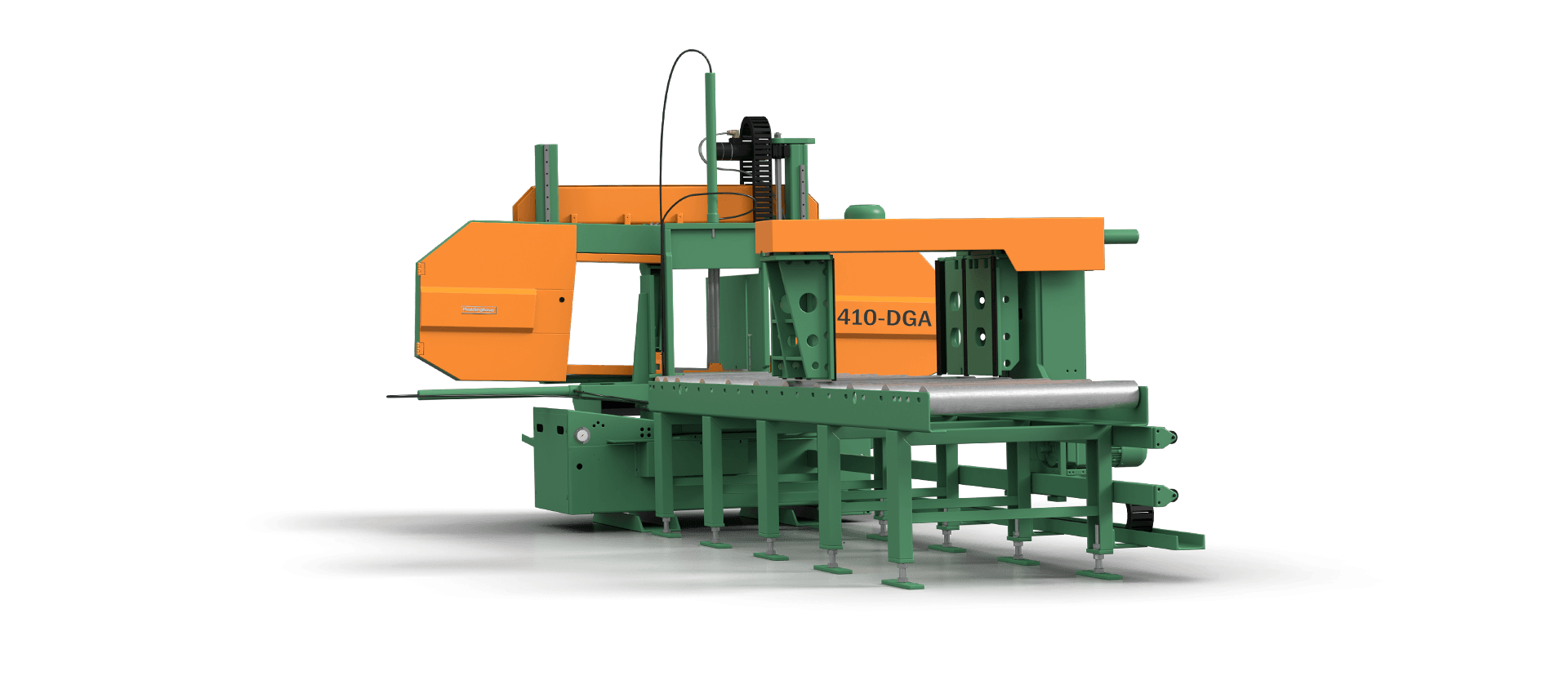

To some, a double miter band saw is just another step in production; a cutting device that merely separates pieces of steel. At Peddinghaus we recognize that every part of your production relies upon this machine to maintain efficiency. Whether they are placed in tandem with a drill line, a CNC layout marking machine or as a standalone sawing solution, these band saws are built for speed and durability.

Twin Column Design

Cutting is facilitated by a 3º attack angle and twin column design on the 410-DGA band saw. This construction eliminates vibration and is critical for cut quality, cut speed and overall blade life.

Miter Cutting Mechanism

The 410-DGA band saw utilizes a double miter design to accommodate 45º and 60º cut angles in both the right and left orientation. Total miter cutting capability can be achieved via program command, or manual input into the saw control.

Superior Saw Clamping

Bundles of material such as square and round tubes can be processed in a single stroke of the saw. The 410-DGA band saw maintains a 19" x 16" (430 x 410 mm) maximum bundle clamp capacity. Bundle clamping is ideal for cutting a high volume of identical sections of material quickly and accurately, increasing overall productivity.

Speed Sawing Technology

Reduce cut times and increase productivity with these saw features: rapid advance blade approach, automatic material sensing, automatic cutting speed transition, feed compensation during the cut, end of cut sensing and automatic retract.

Laser Line Reference

For scenarios where automatic cutting is inconvenient or unavailable, operators can utilize an intuitive laser line reference guide to align cuts. This reference provides ease of use, regardless of the operating requirement.

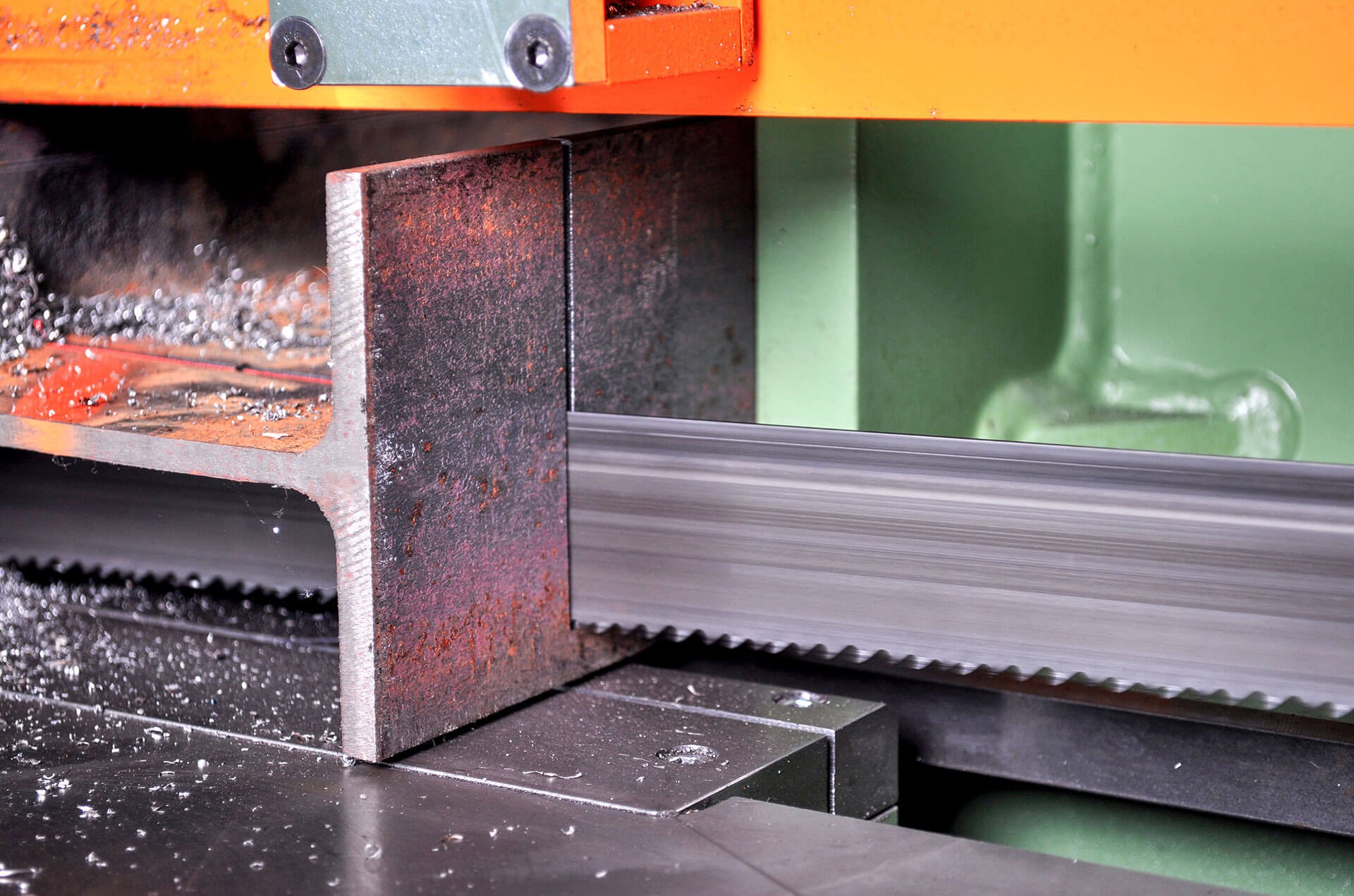

Minimum Quantity Lubricant (MQL)

The 410-DGA double miter band saw utilizes the latest in Minimum Quantity Lubrication systems. Eliminate water-based flood coolant costs by applying this eco-friendly, vegetable oil-based blade lubricant directly to the cutting surface.

Miter Cut Band Saw

To some, a double miter band saw is just another step in production; a cutting device that merely separates pieces of steel. At Peddinghaus we recognize that every part of your production relies upon this machine to maintain efficiency. Whether they are placed in tandem with a drill line, a CNC layout marking machine or as a standalone sawing solution, these band saws are built for speed and durability.

Twin Column Design

Cutting is facilitated by a 3º attack angle and twin column design on the 410-DGA band saw. This construction eliminates vibration and is critical for cut quality, cut speed and overall blade life.

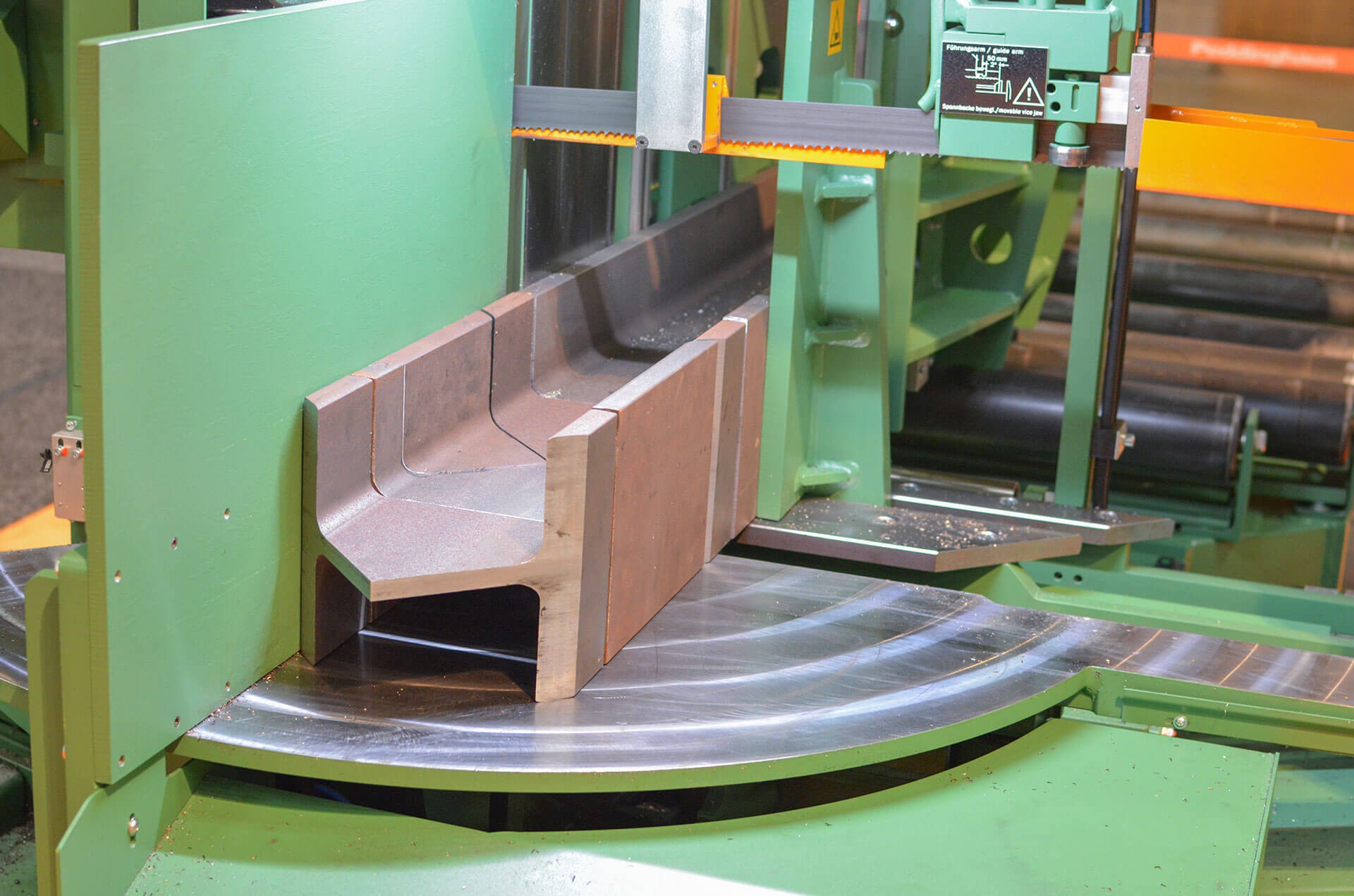

Miter Cutting Mechanism

The 410-DGA band saw utilizes a double miter design to accommodate 45º and 60º cut angles in both the right and left orientation. Total miter cutting capability can be achieved via program command, or manual input into the saw control.

Superior Saw Clamping

Bundles of material such as square and round tubes can be processed in a single stroke of the saw. The 410-DGA band saw maintains a 19" x 16" (430 x 410 mm) maximum bundle clamp capacity. Bundle clamping is ideal for cutting a high volume of identical sections of material quickly and accurately, increasing overall productivity.

Speed Sawing Technology

Reduce cut times and increase productivity with these saw features: rapid advance blade approach, automatic material sensing, automatic cutting speed transition, feed compensation during the cut, end of cut sensing and automatic retract.

Laser Line Reference

For scenarios where automatic cutting is inconvenient or unavailable, operators can utilize an intuitive laser line reference guide to align cuts. This reference provides ease of use, regardless of the operating requirement.

Minimum Quantity Lubricant (MQL)

The 410-DGA double miter band saw utilizes the latest in Minimum Quantity Lubrication systems. Eliminate water-based flood coolant costs by applying this eco-friendly, vegetable oil-based blade lubricant directly to the cutting surface.